Roofer’s Guide to Commercial Flat Roof Options

Primary Commercial Roofing Systems in the United States

When it comes to protecting your building, the roofing system you choose matters. As a manager or owner of a building, it’s important to do your research on the best material types that will (a) provide the most protection (b) last the longest on the roof, and (c) fit a commercial CapEx budget. We’ve put together a quick guide to three flat roof roofing systems that are best for commercial buildings, especially in the upper Midwest.

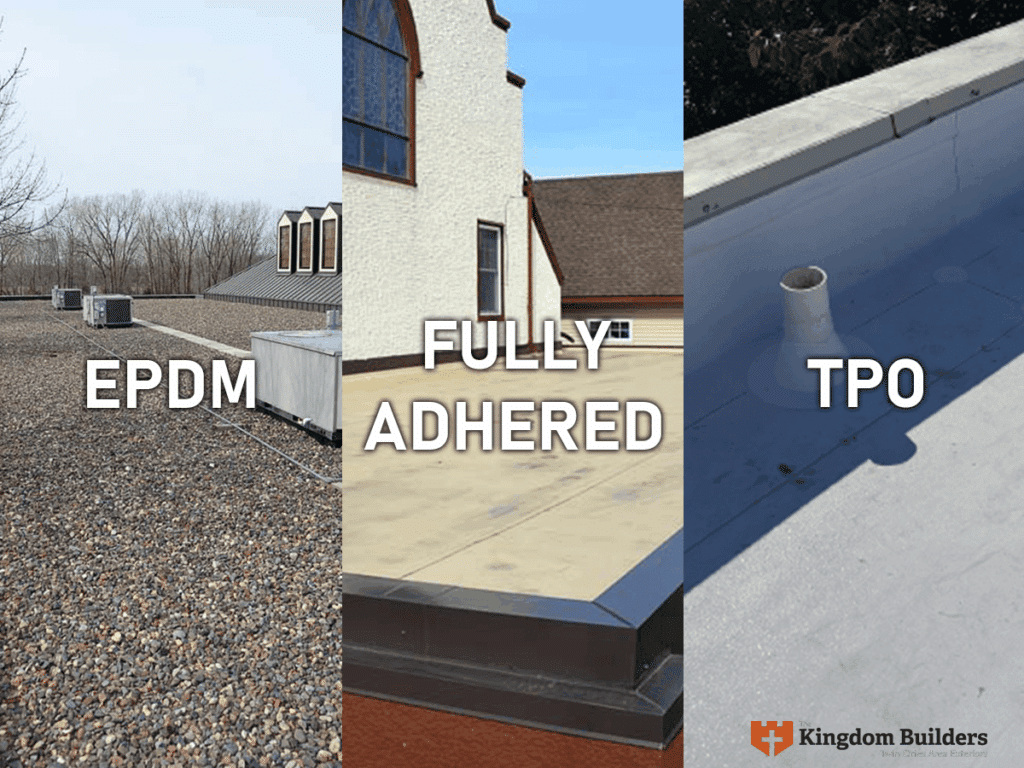

Ballasted EPDM (Rubber)

Mechanically Attached TPO

Fully Adhered

Each system offers unique benefits and challenges. This resource will help you find the option that may best suit your needs.

The Kingdom Builders is a professional roofing company in Minneapolis that has installed many flat roofs. We’ve worked on many commercial jobs, both flat roof and low/steep slope setups. It’s important to note that flat roofing is not a “one size fits all” situation. Every building is different, and having a good strategy for the roof system on any particular building is very important.

Ballasted EPDM (Rubber) Roofing

What It Is: Ballasted EPDM, often called rubber roofing, is a go-to choice for flat or low-slope roofs. This system uses a synthetic rubber membrane (Ethylene Propylene Diene Monomer) laid loosely over insulation and secured with a rock ballast to keep it in place.

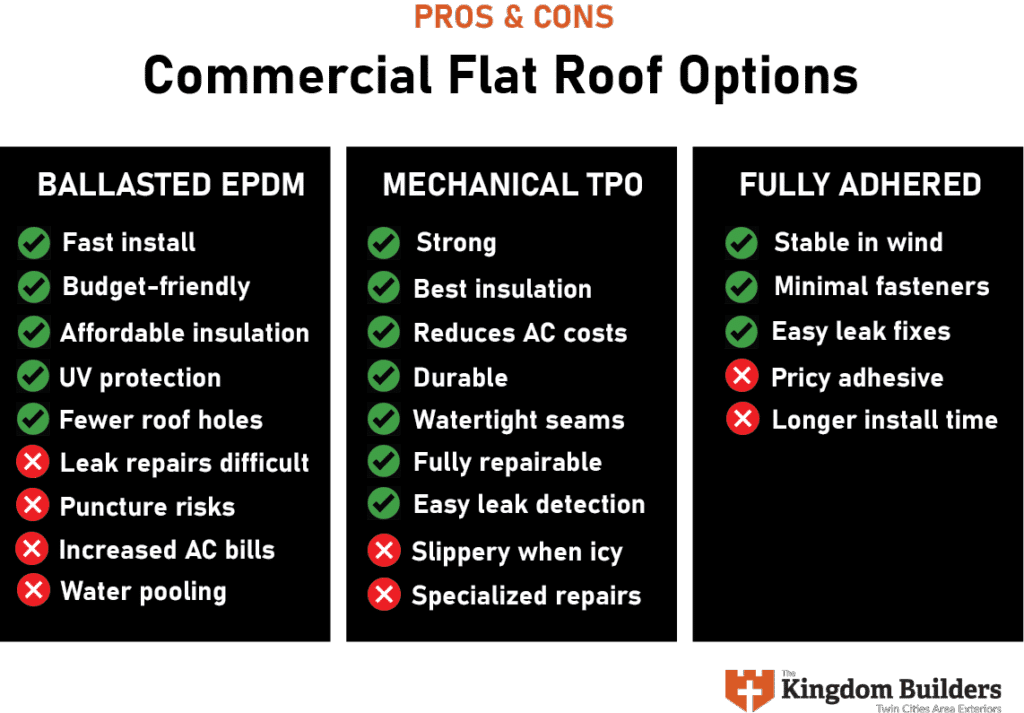

Pros

- Fast Installation: There is minimal attachment to the roof deck, which speeds up the installation process.

- Budget-Friendly Labor: Since the installation is quite fast compared to other options, you will spend less on labor costs.

- Affordable Insulation Options: You can pair it with cost-effective insulation like Expanded Polystyrene (EPS).

- UV & Damage Protection: The ballast shields the rubber from harsh UV rays and physical wear, potentially extending its life.

- Fewer Roof Penetrations: There are fewer deck penetrations in your deck compared to some alternatives.

Cons

- Tricky Leak Repairs: Leaks are tough to find under all that ballast. Fixing them often means moving rocks, which is labor-intensive and costly.

- Puncture Risks: Sharp objects like branches, rocks, or even boots can pierce it, especially if people are walking on it frequently.

- Heat Build-Up: The dark rubber absorbs sunlight, which can hike up your air conditioning bills in summer.

- Insulation Compression: EPS insulation can compress over time, leading to water pooling due to its low PSI rating.

- Shrinkage Issues: Rubber tends to shrink, pulling on seams, parapet walls, and vents, which can cause stress points. This is a larger issue with ballasted roofs, since it’s only adhered in certain areas.

- Glued Seams: Seams rely on adhesive that may break down over time, especially if water gets in.

Best For: Building owners looking for a cost-effective roofing solution with quick installation, who don’t mind potential maintenance challenges down the road.

Mechanically Attached TPO Roofing

What It Is: Mechanically Attached TPO (Thermoplastic Olefin) is a single-ply membrane fastened to the roof deck every 10 feet along seams and around the perimeter. It’s a modern option that blends durability with energy efficiency.

Pros

- Strong: Attached securely to the structure, this system stands up to wind uplift like a champ.

- Top-Notch Insulation: Uses higher PSI-rated insulation with a better R-value, keeping your building cozy and efficient.

- Quick: Installs faster than fully adhered systems without skimping on quality.

- Energy Savings: Its white surface reflects sunlight, cutting cooling costs in summer (and snow covers it in winter, so heat retention isn’t a worry).

- Built to Last: TPO resists punctures, tears, and wear from foot traffic or weather extremes when compared to rubber.

- No Shrinkage: Unlike rubber, TPO holds its shape over time, reducing strain on seams.

- Heat-Welded Seams: Seams are fused with heat for a permanent, watertight bond—no glue to fail here.

- Simple Repairs: No ballast means leaks are easy to spot and fix.

- Multiple Colors: There is a much wider variety of colors available compared to rubber roof options.

Cons

- Specialized Repairs: You’ll need TPO welding equipment (think: a pricey, high-tech hairdryer) for fixes, so DIY isn’t an option.

- Slight Rippling: Normal waviness between attachment points might bug perfectionists, though it’s purely cosmetic.

- Slippery When Icy: The smooth surface can be a hazard in freezing conditions.

- More Fasteners: More penetrations than ballasted systems.

Fully Adhered Roofing Systems

What It Is: Fully adhered systems bond the membrane (EPDM, TPO, or PVC) directly to the insulation or deck with adhesive, creating a tight, seamless fit across the entire roof.

Pros

- Unmatched Stability: Glued down across every inch, this roof won’t budge (even in high winds) and resists shrinking or shifting.

- Easy Leak Fixes: No rocks to move; leaks are straightforward to locate and repair.

Cons

- Pricey Adhesive: Bonding glue is expensive and can cost around $3,100 for a typical roof.

- Labor-Heavy Install: Applying adhesive is a meticulous, time-consuming job that drives up labor costs significantly.

- Longer Install Time: Expect it to take twice as long as mechanically attached systems, weather permitting.

- Fume Factor: The adhesive off-gasses during installation, creating strong odors that might bother anyone nearby.

Best For: Building owners who want maximum durability and don’t mind investing more upfront for a low-maintenance, wind-resistant roof.

Considerations

Picking the best roofing system boils down to your priorities as a business. If you need something affordable and quick, Ballasted EPDM would be our go-to. If you are looking for long-term energy savings and/or durability, Mechanically Attached TPO is the best pick. The lowest maintenance option on this list is a Fully Adhered system.

Fun fact: reflective roofs like TPO can cut energy use by up to 30% in summer, according to the U.S. Department of Energy—something to think about if cooling costs are a concern!

Professional Advice

At The Kingdom Builders, we’ve got years of experience installing and maintaining all these roofing types. We’ll walk you through the pros and cons, tailoring our advice to your budget, building needs, and long-term goals.

Don’t let roofing decisions stress you out. Contact The Kingdom Builders today for a no-pressure consultation. Our experts will help you choose and install a roofing system that keeps your building safe, efficient, and looking great for years to come. Call us now or fill out our online form—let’s get started on your perfect roof!

Josh Clark

Josh Clark is a Project Manager for The Kingdom Builders. He has over a decade of experience in the roofing industry, overseeing crews, scheduling projects, and doing marketing efforts.